Matt Nuccio: “The other Italian family business” - tBR Person of the Week

I was fortunate to grow up in the toy business before it became the industry it is today. My father, Mark Nuccio, started his career as a paste-up mechanical artist working with Ideal Toys and Aurora before eventually becoming the vice president in charge of product development, packaging, and marketing at HG Toys. As a teenager, my parents started Design Edge out of the family garage on Long Island in New York. It was a family affair. My mother, in a leap of faith, left her art-teaching career behind to focus on illustration. My sister, at the time, a freshman at the School of Visual Arts took a semester off to help get Design Edge off the ground. I was a 14-year-old and drafted from day one. In the next few years, there would be no family vacations, as we would all sacrifice for the greater good that was Design Edge. …Or as we say, “the other Italian family business.”

(Mark Nuccio circa 1982 - HG Toys)

In the late 1980s, early 90s, the toy industry was in a major transition. Our clients ranged from old school cigar-chomping “Toy Guys” to the new and cutting edge breakout companies like Toybiz, ToyMax, and JPI (soon to become Jakks Pacific). Many of these companies worked out of the now-defunct International Toy Center (aka the Toy Building) located at the corner of 23rd Street and 5th Ave, across from the famous Flatiron in New York City. As a teenager, I was often asked to take the train and subway from Long Island to the Toy Building to deliver or pick up whatever was needed. This was NY’s Mayor Dinkins’ era. Crack was at its height, the subways were still covered with graffiti, and there was a chance of being mugged at seemingly every corner. And, while the city was gritty, the old cigar-chomping Toy Guys were grittier …and while these guys’ day-to-day business consisted of figuring out ways to screw everyone from the inventors to retailers and everyone in between out of money, they took to me and mentored me in ways that school or a corporate career never could. They broke the moving parts of the toy business down to their essentials: inventions, trends, manufacturing, sales.

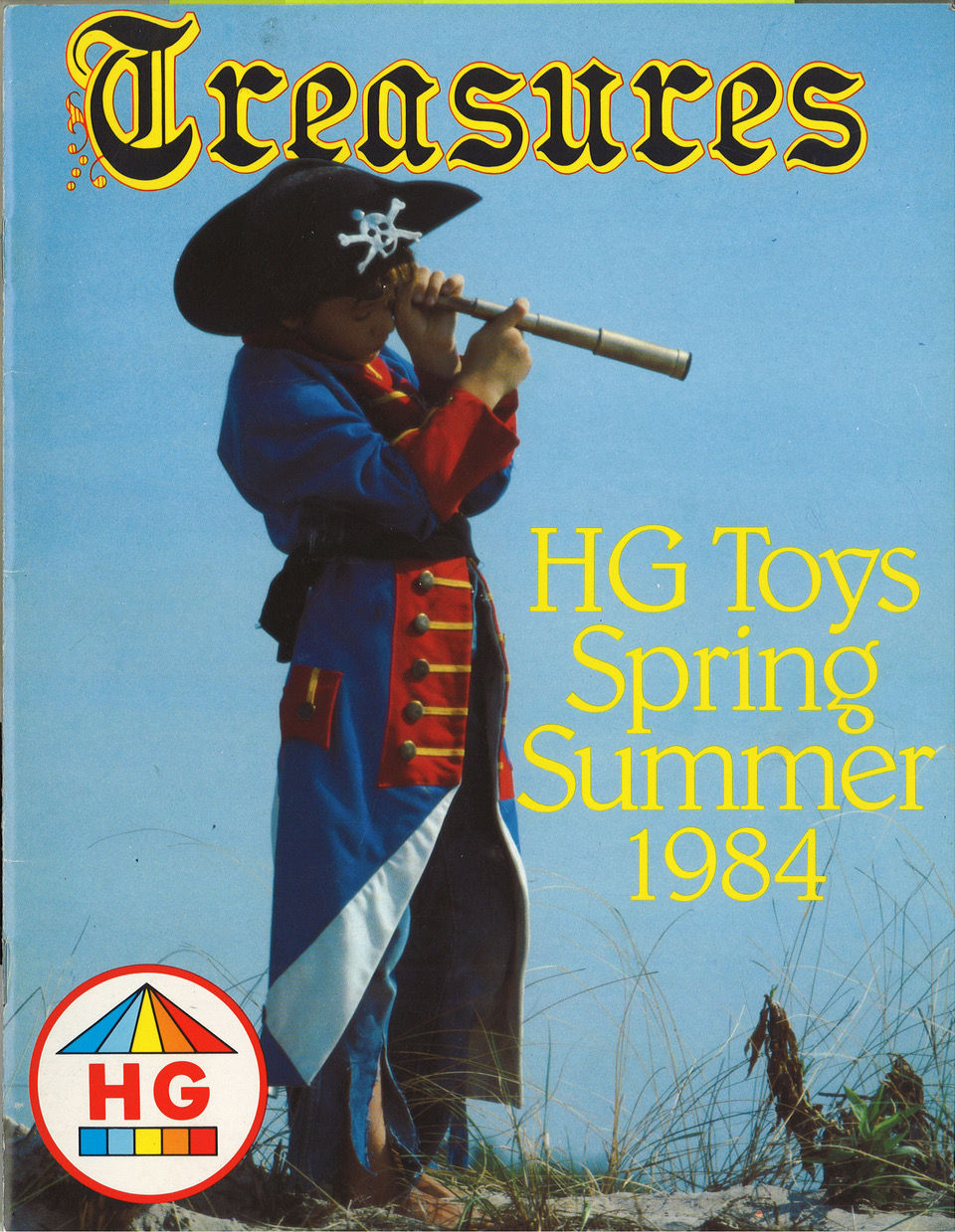

(Matt Nuccio on the cover of the 1984 HG Toys Spring Summer catalog)

Inventor

It is no secret that toy inventors generally get the short end of the stick when it comes to making money off of their inventions. Unfortunately, there is no system in place to protect toy inventors from bad deals like there are in other industries. For instance, it has become common knowledge about the horrible deals musicians once were forced to sign. Many of these musicians eventually died broke --even after having written and/or recorded some of the world’s most famous songs. Songs that record labels made millions on. Eventually, the ASCAP was organized to create a blanket license agreement to ensure that musicians were properly compensated for their contributions. The same is true of the Hollywood studio system area of actors, also many dying broke after having massive success in their respected heydays. And, so, the Screen Actors Guild (SAG) was created to protect their interests. Yet we still have no such protection in the toy industry.

How do toy inventors get screwed? On my many trips to the toy building, I would often be a fly on the wall sitting in front of some old “Toy Guy’s” desk, wood paneling on the wall, stained red carpet on the floor, and dirty ashtrays on practically every table surface. I would just be waiting for them to get off the phone to review the project at hand. In one particular instance, I witnessed two inventors licensing negotiation on an old school telephone speaker box. The inventor was demanding a royalty of 10% and was negotiating hard. The Toy Guy never conceded just telling the inventor that he heard his argument and would think about it. After he got off the phone he turned to me and said something to the effect of “kid, that guy’s a moron. I can give him 10% on paper and he’ll be lucky if he nets 1% after all the deductions.” He went on to explain to me that a royalty rate is only as good as your definition of net and gross profit. He could put his daughter on the books with a no show job for 10 million dollars a year…Poof, there goes the profit. It would be years before I would really understand what he was telling me. After having many poor licensing contracts myself I started to realize that my lawyers just didn’t understand the toy business and would leave gaping loopholes that companies would always take advantage of.

(Design Edge ad circa 1988)

Trends

Toy design is a fashion design business. Just like shoes, handbags, and clothes, toys have a season, a trend, and a demographic. What is popular today will be gone tomorrow. While you may say “of course it is” you may like to know that this is not a necessity or an accident. The International Toy Building was situated only a few short blocks from New York’s famed garment district. Garmento’s, an old term for someone in the garment industry in New York, and Toy Guys came from the same neighborhoods, ate the same foods, socialized together, and at times, even manufactured products for each other while some companies even had their own lines of both; toys and clothes. Early on, Toy Guys saw how the garment business was able to secure repeat business by creating trends and ending trends and so the toy business followed suit. An old Toy Guy once told me, “Matt, if you want to make money in the toy business you need to find the right item and pick the dollar amount you want to earn. Once you hit that dollar amount, you stop producing and start all over again with a new item.” Initially, this didn’t make sense to me. Why wouldn’t you just keep selling an item especially if it’s a hit? Well… as I learned time and time again, hits fall off cliffs and when they fall off these cliffs it costs a lot of money in markdowns, order cancelations, and liquidation. Sometimes, it can cost far more than you made.

Manufacturing and Sales

When it comes to sales, I hear the same expression time and time again to this day, “your money is made on the buy, not the sell.” And while that has been accepted by many as an irrefutable truth handed down from the old Toy Guys to corporations of today, there is more to it than just the best dollar amount and all the old Toy Guys knew that. You see, many of the old Toy Guys I knew worked in a completely different industry than the one we work in today. They actually made their own products in their own factories. And, while they worked hard to make it at the best price, they also had an excellent understanding of the manufacturing process. They made sure they bought the right materials for the right price. They reviewed how the product was molded to ensure the best output. They set up the production lines according to deliverables and understood the nuances of engineering a toy. Today, the majority of the toy industry is not producing its products but just simply “buying at the best price.” It is a very dangerous game. The key is, to get the best price at the best quality now largely rests on good design and engineering. And, as the toy industry of today strays more and more from understanding the processes to which toys are made, I am sure there are dozens of old Toy Guys spinning in their graves.